What is this stuff called Epoxy?

Rockstars 7 June 0 CommentsEpoxy

There are many forms of epoxy such as: Casting epoxy, glue epoxy, epoxy coating for floors, etc… For the purpose of our blog today we will discuss how we use epoxy in a floor coating application.

Epoxy is a coating that consists of a base that can be coloured and a hardening agent (AKA Catalyst) that mix together to create a cross-linking action. When epoxy is fully cured it is a surface that is quite rigid, durable, repairable and looks fantastic.

You may hear the work Polyaspartic as well. For all intensive purposes the two are the same with one difference. Epoxy is NOT UV (Ultra Violet – Sun resistant) but Polyaspartic is.

Our decision to use one or the other can be based on the UV resistance requirements as well as time access to the surface we are coating. Polyaspartic, although more costly dries faster, therefore possible a one day vs two day application (depending on surface prep and surface square footage).

Both Epoxy and Polyaspartic can be used in the same way. The surface can be finished in a solid colour, flakes (most common) or metallic (used inside a home only).

Solid colours – are often used in workshops, warehouses and garages. There are many options for colours and added slip resistance can be used as well as a solid colour is more likely to have less grip than flakes.

Epoxy Flakes are multi-coloured paint chips that are broadcast into the epoxy base coat as a striking clean look and add to the scratch resistance as imperfections tend to be covered up in this process. The final process in this system is a clear-coat used to protect the flakes and provide an extremely durable surface.This process is the most popular method used in garages or commercial spaces.

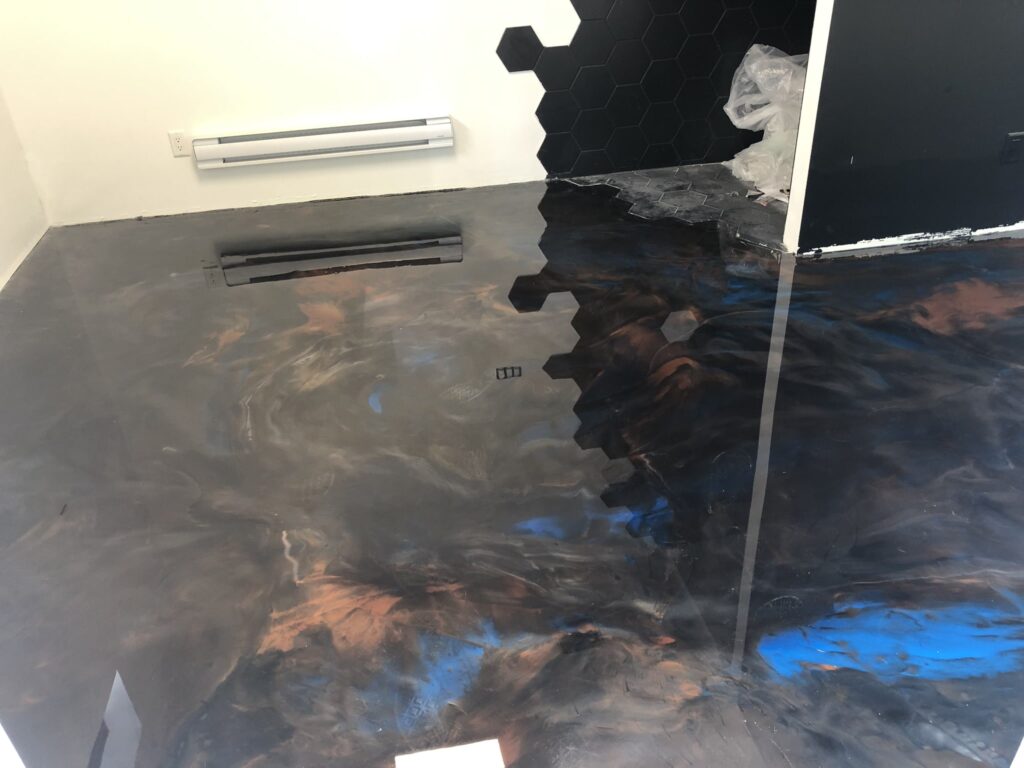

Metallic is best used in an area where design is the main purpose and resistance to scratching is not, such as an inside office or living room. Metallic is often used for very interesting design work and can look like marble artwork when completed. Metallic in a garage where rocks and chemicals will be a factor is not suggested.

No matter what process is chosen we take the time to ensure you have made the right choice. Our work is carefully carried out as we prepare the surface by grinding the surface then filling cracks and imperfections prior to the coating being applied. This process is extremely important in ensuring the final look is correct and the coatings adhere to the surface for many years. Results like this garage can be seen on our website as well as many other aspects of our business.

We hope this post gives you an idea of what epoxy is all about and of course we can be contacted anytime with questions.

Leave A Comment

Your email address will not be published. Required fields are marked *